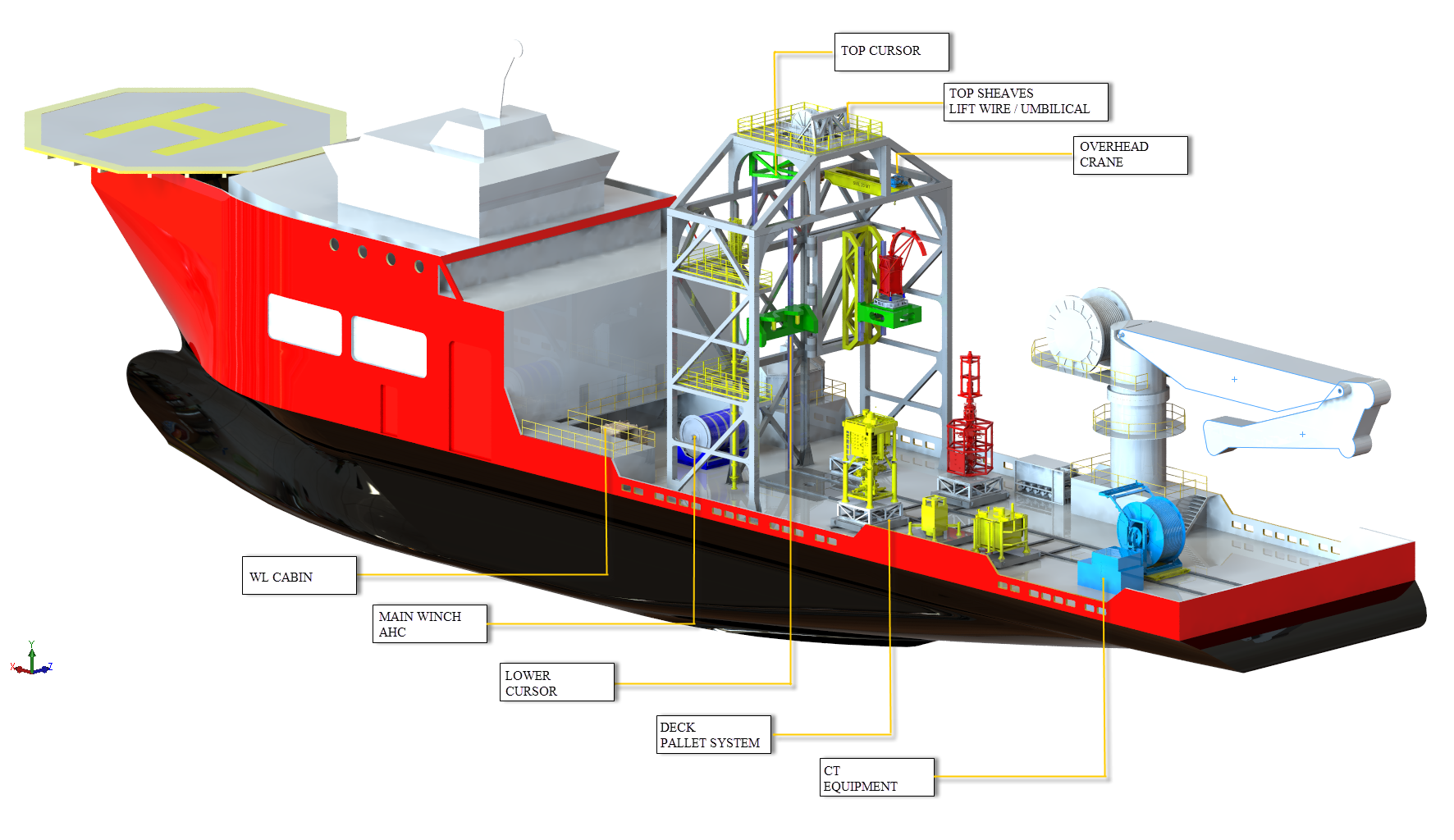

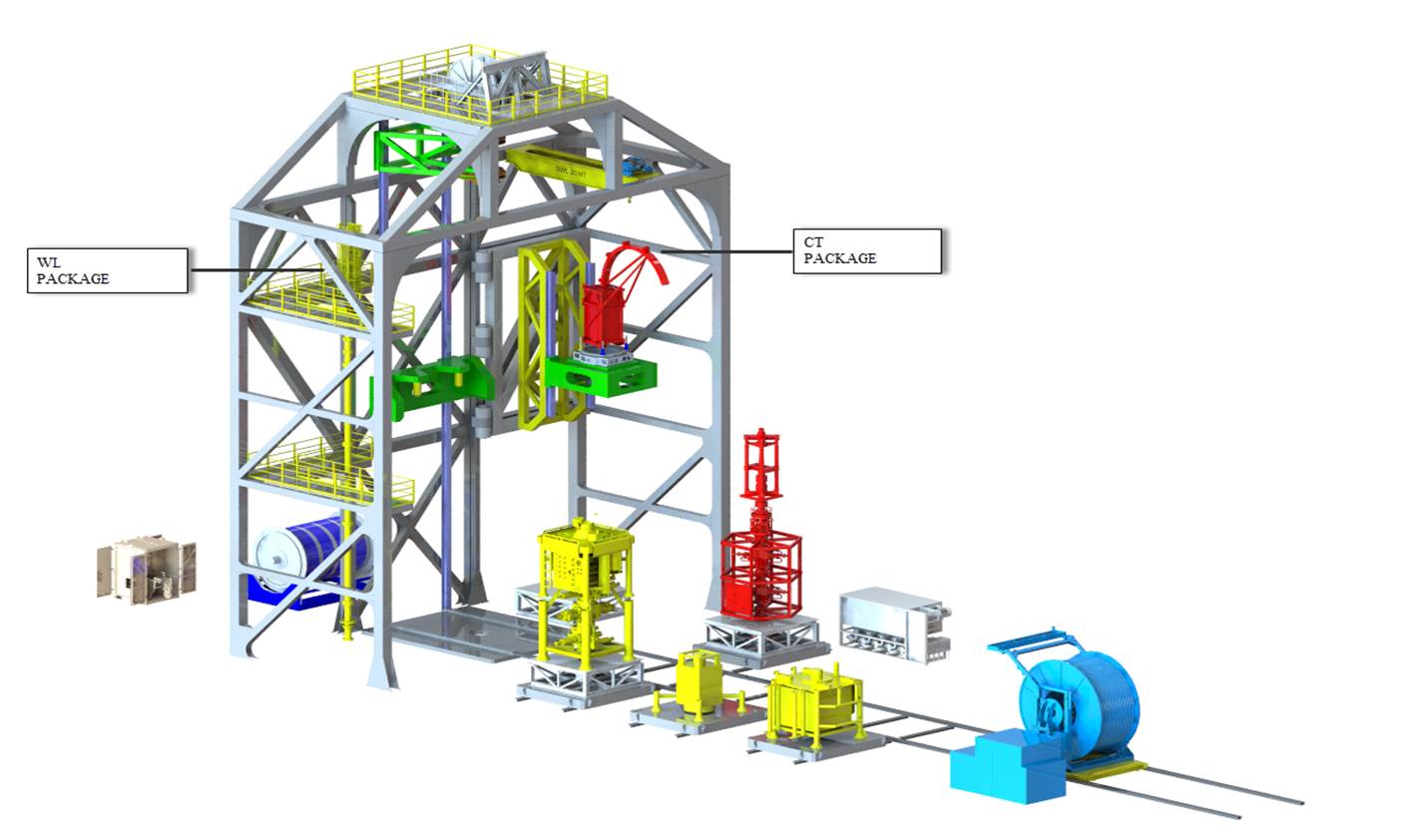

Dwellop offers bespoke boat towers for running module handling and subsea well intervention (Riserless Light Well Intervention – RLWI). The towers can utilize fibre rope or steel rope winches for deployment. Moonpool and cursor systems are custom engineered for each vessel.

RLWI Solutions

Technical overview

RLWI Environment

Offshore Oil Fields

Classification

DNV

Max. water depth

2 000 m / TBA

Main hoisting system

Fiber-Rope Traction Winch (DeepTek)

SWL 150 MT (single fall)

AHC / PHC Tensioner mode available

Max. hook height

32 m

Max. RLWI stack height

30 m

Cursor system

SWL15 MT Winch

Lower Cursor (master mode)

Upper Cursor (slave mode)

Guiding Arm

Guide line system

4x SWL 5 MT Winch

600 m effective wire length

Guided on adjustable guiding arms

AHC / PHC Tensioner mode available

Pod line system

2x SWL 10 MT Winch

Guided on adjustable guiding arms

AHC / PHC Tensioner mode available

Umbilical winch

2 000 m effective umbilical length

Passive motion compensation system

Skidding system

Deck-Skid Pallet System

Foot Print 4×4 m, SWL 150 MT

Sea fastening system

Moon pool hatch

2x Folding Down Side Hatch

1x Folding Down Central Rail, SWL 150 MT

RLWI stack test and storage

Dedicated area for Vertical Test and Storage of RLWI stack outside of moon pool section with attached umbilical and wireline

Cherry picker

2x Personnel Lifting, SWL 250 kg

Cargo Lifting, SWL 1 MT

Access platforms

Access to critical maintenance areas by effective staircase system

Control cabin

Safe and Effective Control Center

Equipped with Tower and ROV operator’s chairs, HMI panels

Pressurized system with dedicated HVAC unit

ATEX approved

Overhead Crane

SWL 20 tons

Options

- Deck skidding system with multiple skid pallets and XY pathways

- Moon pool hatch including cursor interface

- Tower structure including two cursors and steel wire rope winch

- LER and HPU

- Tower Control Cabin

- Coiled Tubing subsea stack handler

- Coiled Tubing HC injector handler

- Coiled Tubing tool handler

- Wireline subsea stack handler

- Wireline HC wire handler

- Wireline tool handler

Let’s talk about your project.

If you have any requirements or need further information, please don’t hesitate to contact us.